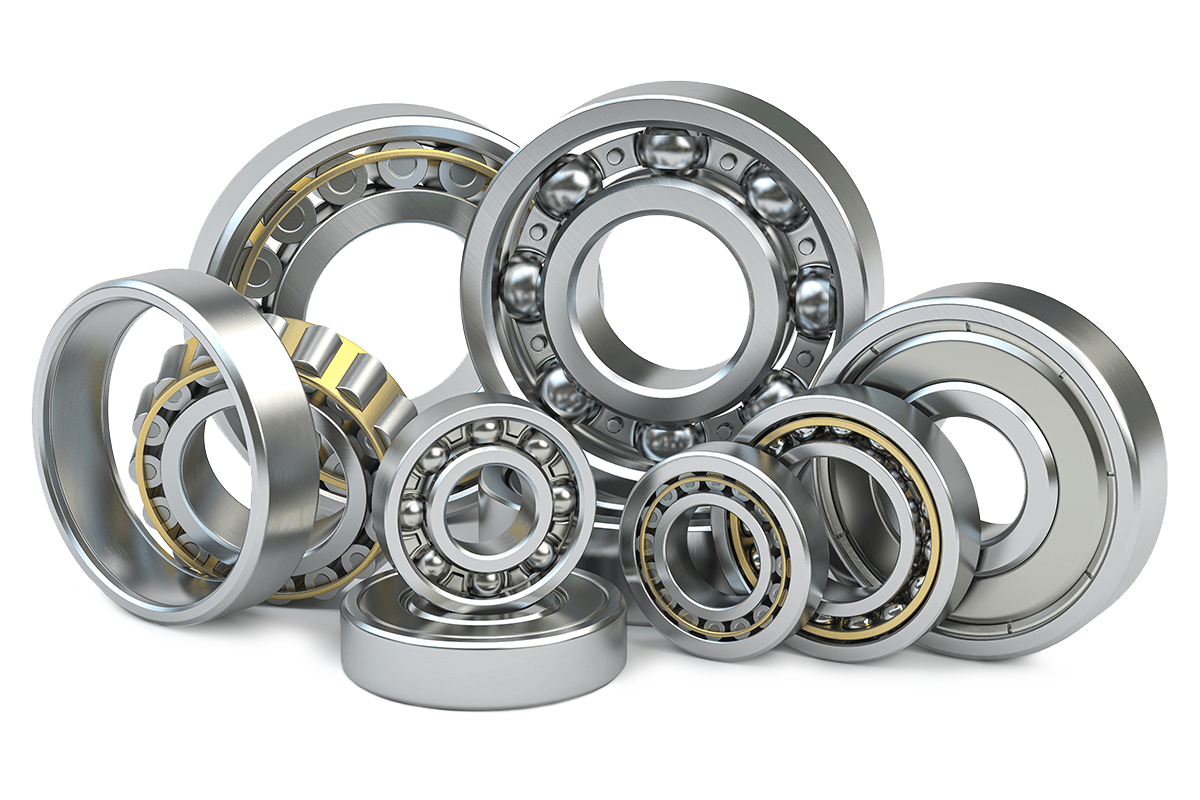

Industrial lubricants are substances used to reduce friction between two surfaces. Their most essential function is to prevent direct metal-to-metal contact between the rolling elements, raceways and cages of bearings, and also between other tools, finished parts, or industrial machinery.

Lubricants also slow down wear and protect surfaces against corrosion through the removal of moisture.

Studies have shown that poor or incorrect lubrication accounts for approximately 36% of all premature bearing failures. Therefore, the choice of a suitable lubricant as well as method of lubrication for each individual application is vital, along with correct maintenance.

Choosing the right lubricant requires considering a variety of factors, most importantly, the operating conditions and the intended application. Factors to consider are also the temperature range and speeds of application, as well as the surrounding environment. For example, when there is high risk of exposure to contaminants, chemicals or water; high temperature or extreme condition grease may be recommended.

Receive Genuine products from SLS. Your business Partner to safeguard against Counterfeit. Want to learn how to identify counterfeit products and verify the authenticity of your bearings?

Read More

Contact Us

Contact Us